コレクション minimum yield stress formula 197954-What is minimum yield stress

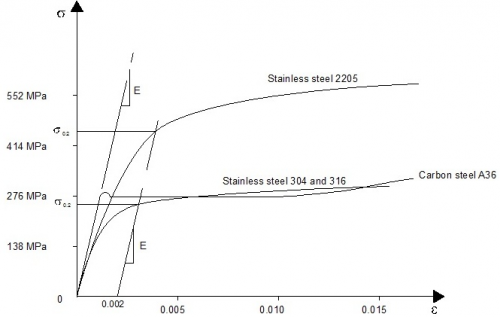

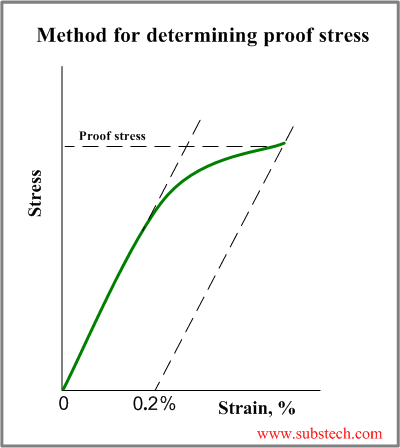

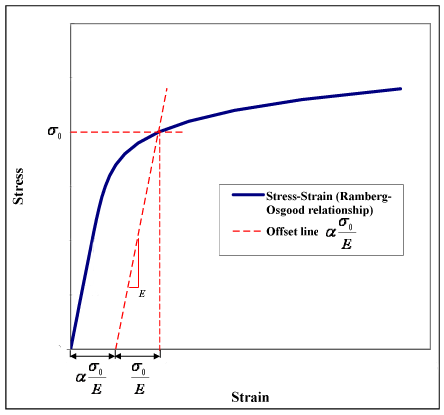

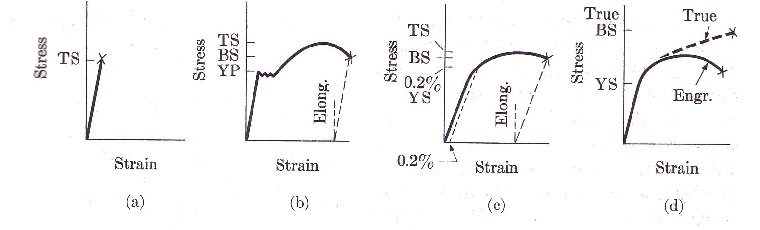

The 02 Percent Offset Rule The most common engineering approximation for yield stress is the 02 percent offset rule To apply this rule, assume that yield strain is 02 percent, and multiply by Young's Modulus for your material σ = 0 0 0 2 × E \sigma = 0002\times E σ = 0002×ELoad reversals (2 reversals = 1 cycle)!The traditional method for determining yield stress on a rotational rheometer or viscometer was by fitting models to the measured rheograms and extrapolating to zero shear rate This article discusses various yield stress calculation methods

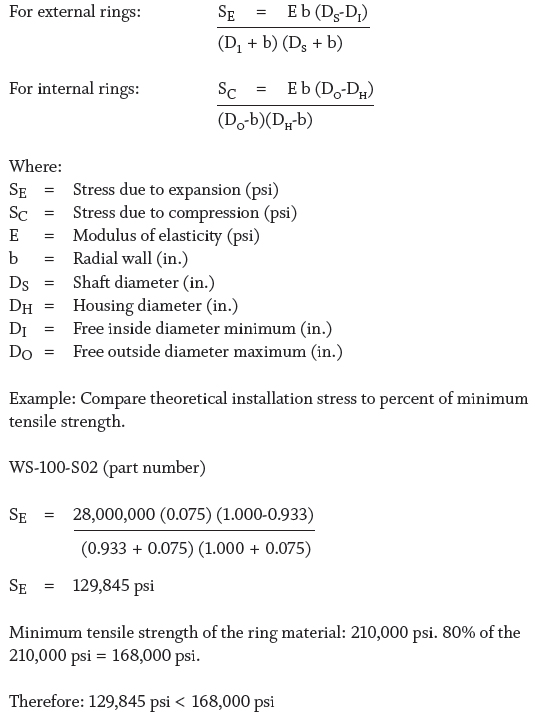

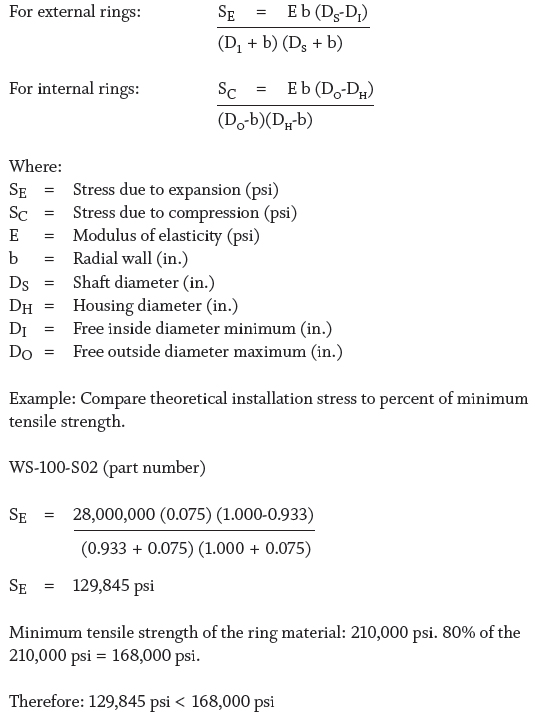

Careful Calculations Affect Ring Design

What is minimum yield stress

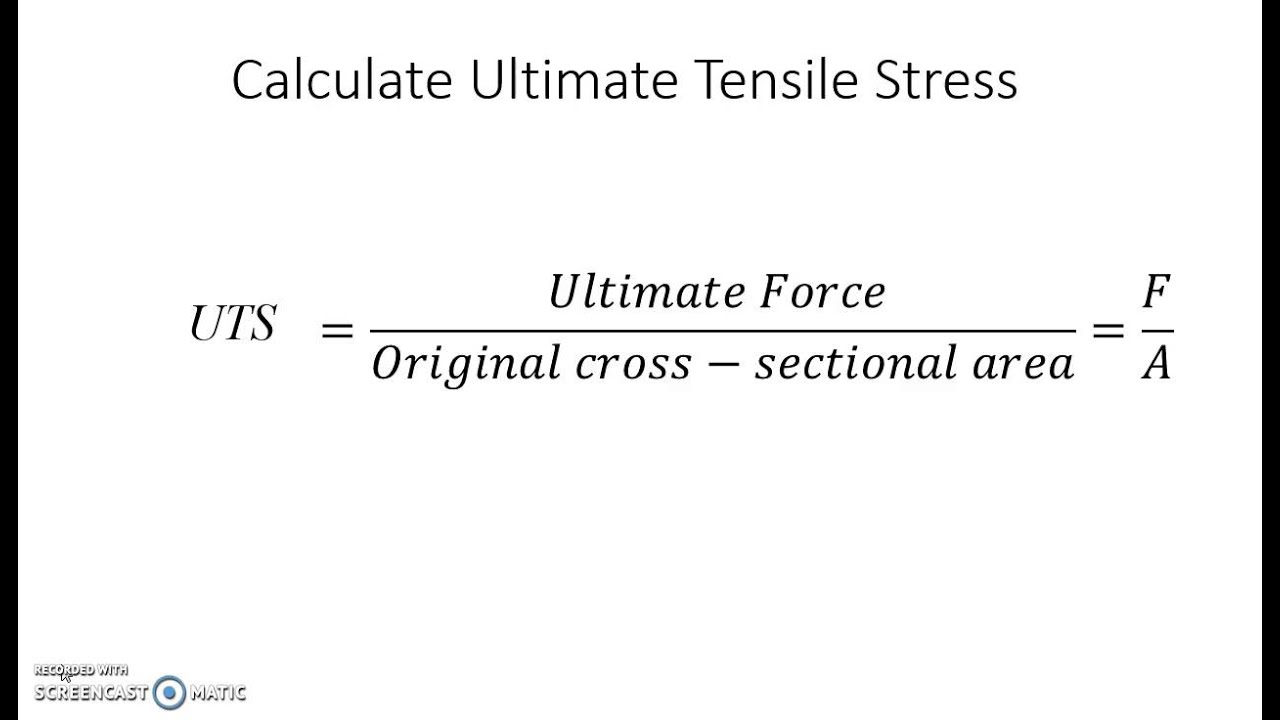

What is minimum yield stress-Yield strength equals approximately one third of the material's hardness, measured in pounds per square inch, but your manufacturer will provide an exact figure If the material yield strength equals 30,000 pounds per square feet and the wall thickness is 3 inches 30,000 x 3 = 90,000 Multiply your answer by 2AISI 1008 CRS has a UTS of 49,300 psi and min YS of 41,300 Given material thickness and bend length as above, the current value I was using for "average yield strength" resulted in a "bottoming" force of 45,300 x 063 x 10 / 00 = 1427 tons Substitution comes up with 49,560 x 063 x 10 / 00 = 1561 tons

.jpg)

Yield Stress Calculation Methods

S t = specified yield strength of material often 60% of yield strength (psi) Wall Thickness Barlow's formula can be useful to calculate required pipe wall thickness if working pressure, yield strength and outside diameter of pipe is known Barlow's formula rearranged t min = P i d o / (2 S y) (5) whereMin a Mean stress!Where P = ID pressure (psi) T = Wall thickness (in) OD = Outside Diameter (in) *Must be a decimal* SF = Safety factor (generally 15 – 10, 1 for collapsing pressure) S = Material strength (psi) *Minimum yield strength*

To maximize (or minimize) the stress, the derivative of σ x′ with respective to the rotation angle θ is equated to zero This gives, dσ x′ / dθ = 0 (σ x σ x) sin2θ p 2τ xy cos2θ p = 0 where subscript p represents the principal angle that produces the maximum or minimum Rearranging gives,The term SMYS is defined in §1923 of 49 CFR Part 192 to mean specified minimum yield strength As an example, Trade B pipe made to API 5L specification has a specified minimum yield strength (SMYS) of 35,000 pounds per square inch (psi) 40 percent of SMYS (35,000 x 040) is 14,000 psi6 Specified Minimum Yield Strength >3,500 psi 7 Maximum Allowable Operational Pressure (MAOP) 125 psi According 16 NYCRR §, the design pressure formula for plastic pipe is the following p = 25 x 032 SDR 1 Where P= Design Pressure, psig S= Hydrostatic Design Basis (HDB) at pipeline operating pressure, psig

Twothirds of the specified minimum yield strength (which is at room temperature) Twothirds of the "minimum" yield strength at temperature Average stress for a minimum creep rate of 001%/1000 hours Twothirds of the average stress for creep rupture in 100,000 hoursNote that the equation for maximum compressive stress is a function of the average stress, P/A, and so the value P crit/A is the value of the average stress at which the maximum compressive stress in the column equals the material yield strength σ crit = P crit / A611 Characterizing Fluctuating Stresses!

Characteristic Strength Of Materials Characteristic Load Or Ultimate Load

113 Questions With Answers In Yield Strength Science Topic

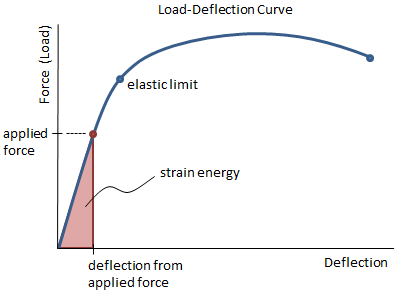

The minimum threshold stress required is 80 percent of specified minimum yield strength API P110 Minimum Yield Strength 110,000 psi Maximum Yield Strength 140,000 psi Minimum Tensile Strength 125,000 psi Hardness Requirement None Notes API grade for general use in deep wells This grade is not generally considered suitable for sourS = minimum yield strength of pipe, psi F = design factor E = longitudinal weld joint factor (see ANSI 13);At the yield stress point the material has reached the maximum elastic energy that it can store without causing a change in molecular arrangement In most materials the tensile yield stress is less than the compressive yield stress, so generally the term Yield Stress refers to tensile yield stress

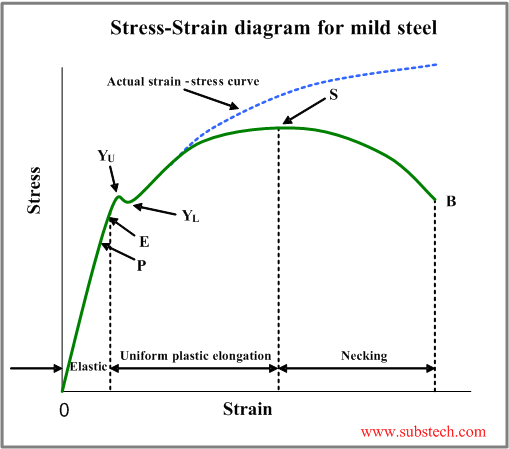

Tensile Test And Stress Strain Diagram Substech

Yield Strength Strength Mechanics Of Materials Engineers Edge

Barlow's Formula is an equation which shows the relationship of internal pressure, allowable stress, nominal thickness and diameter You can use Trident Steel's calculator tool to determine bursting pressure of line pipeTrident Steel offers ERW line pipe from international and domestic millsUse our calculator below or get a quote on line pipe todayThe stressstrain diagram for a steel rod is shown and can be described by the equation ε=0(1e06)σ0(1e12)σ 3 where s in kPa Determine the yield strength assuming a 05% offsetThe formula is expressed as P=2St/D, where P = pressure, psig t = nominal wall thickness, in inches(ie 375) D = outside Diameter in inches S = allowable stress in psi, which depends on the pressure being determined utilizing Yield or Tensile depending on what is trying to be determined For example Internal Pressure at Minimum Yield

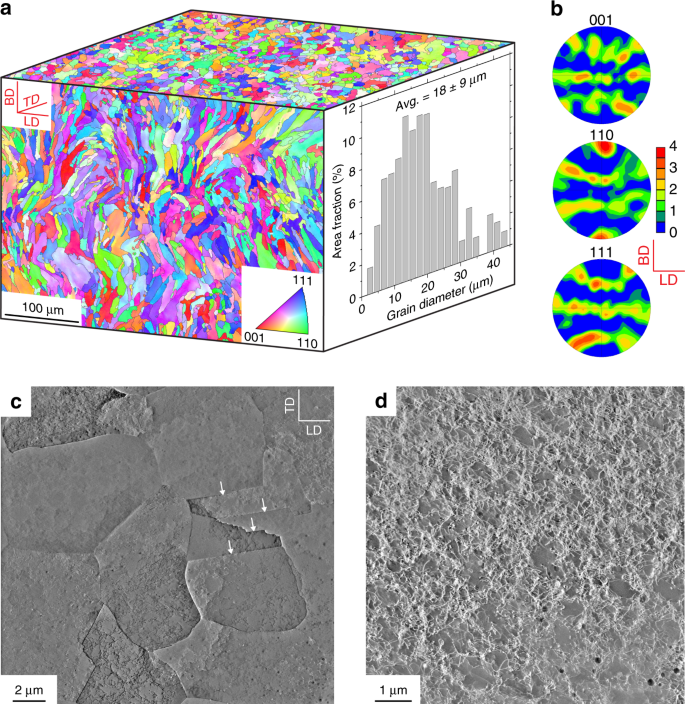

Microscale Residual Stresses In Additively Manufactured Stainless Steel Nature Communications

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Mill Hydrostatic Test Pressureσ y = yield stress, 262 MPa σ a = allowable bending stress, 055 σ y =1441 MPa τ a = allowable shear stress, 033σ y =8646 MPa σ t = allowable fatigue stress, 255 MPa D a = allowable deflection, L/800, m P m = concentrated load for moment, 104 kN P s = concentrated load for shear, 155 kN LLIF= live load impact factor, 1 50 (LIt is an indication of the minimum stress a pipe may experience that will cause plastic (permanent) deformation The SMYS is required to determine the Maximum Allowable Operating Pressure (MAOP) of a pipeline, as determined by Barlow's Formula which is P = (2 * S * T)/(OD * SF), where P is pressure, OD is the pipe's outside diameter, S is the SMYS, T is its wall thickness, and SF is a Safety Factor

Calculator For Applying Ductile Failure Criteria

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

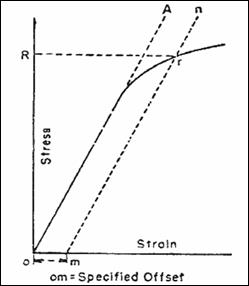

Then on the stressstrain diagram, lay off om equal to the specified value of the offset (ie yield strength ~02%), draw mn parallel to OA, and thus locate r, the intersection of mn with the stressstrain curve corresponding to load R, which is the yield strength load In recording values of yield strength obtained by this method, the valueDesign Formula for Steel Pipe P = (2St/D) x F x E x T • Step 1 Choose a pipe and enter "S" (Yield Strength), "t" (Wall Thickness), and "D" (Outside Diameter) For new pipe this should be straight forward For existing pipe, you need to rely on existing records If "S" is unknown, use 24,000 psi orThe stressstrain diagram for a steel rod is shown and can be described by the equation ε=0(1e06)σ0(1e12)σ 3 where s in kPa Determine the yield strength assuming a 05% offset

Stress Strain Curves Of Metallic Materials And Post Necking Strain Hardening Characterization A Review Tu Fatigue Amp Fracture Of Engineering Materials Amp Structures Wiley Online Library

Calculate Yield Stress Youtube

Determined with a concrete strain of 0003 and tensile strain of 0004 (minimum) When the strain in the reinforcement is 0005 or greater, the section is tension controlled (For smaller strains the resistance factor reduces to 065 – see tied columns because the stress is less than the yield stress in the steel)Hoop stress formula Maximum allowable hoop stress (specified minimum yield stress, SMYS) USA ASME 14 and BS318 =P·OD/(2·t min) 072 UK PD8010 =P·(OD−t min)/(2·t min) 072 Netherlands NEN 3650 =P·(OD−t min)/(2·t min) 072 Canada CSAZ1 and Z184 =P·OD−/(2·t nom) 08 ISO =P·(OD−t min)/(2·t min) 077Maximum Allowable Operating Pressure S = SMYS reduced by a design factor;

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

Smts And Allowable Stress Amarine

Maximum stress, σ max!!Midrange stress, σ m!!2 F F max F min m = 2 F F max F min a − = Terms for Stress Cycling!

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

1 1 11 Pipe Thickness Calculations Pipe Fluid Conveyance Building Materials

In order to get around this, the Minimum Yield Stress σ ymn figures are divided by 1 psi to get around Mathcad's unit enforcement The result is the same as would be achieved with a calculator, ignoring unitsS tensile = t min x a Shear Strength of a thread S sy = p r x s yield Where ymin = Minimum Yield of bolt threads engaged (lbs) s yield = Minimum yield strength of the bolt grade, ASTM, SAE, etc (psi) s tensile = Ultimate Yield Strength (lbs) t min = Minimum tensile strength of the bolt grade, ASTM, SAE, etc (psi)The yield point happens after an object has reached its yield stress This example is of steel Steel materials have a yield point, which causes them to have a large horizontal portion of the graph

What Is The Difference Between Tensile And Yield Strength Quora

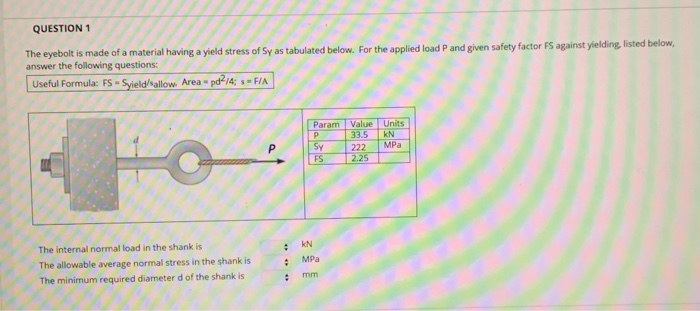

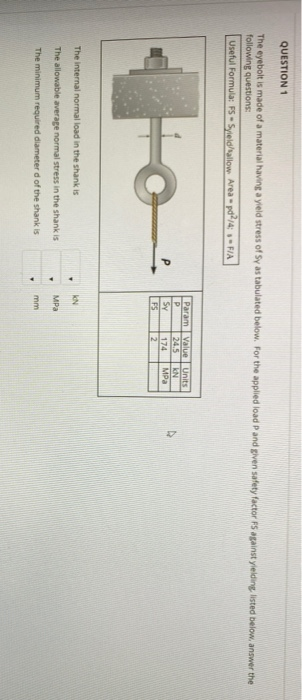

Solved Question 1 The Eyebolt Is Made Of A Material Havin Chegg Com

When the circumferential stress on the inner wall of the casing reaches the minimum yield strength under external collapse pressure, the yield failure of casing is generated, as shown in Equation (52) (52) p YP = 2 Y P ( D / t) − 1 ( D / t) 2 The usable range of Equation (52) is D/t ≤ (D/t) YPYield in ductile materials is usually caused by the slippage of crystal planes along the maximum shear stress surface Therefore, a given point in the body is considered safe as long as the maximum shear stress at that point is under the yield shear stress obtained from a uniaxial tensile testMax min σ σ R= Stress Amplitude!

Steel Material Properties Steelconstruction Info

Minimum Yield Stress An Overview Sciencedirect Topics

S = allowable stress, psi To illustrate, assume a seamless piping system 85/8" OD x 0375" wall specified to API 5L Grade B which has a specified minimum yield strength (SMYS) of 35,500 psi and a specified minimum tensile strength (SMTS) of 60,0 psi Internal Pressure at Minimum Yield S=SMYS (35,500 psi) andStress amplitude, σ a!!= 100 for seamless, electric resistance weld, flash weld = 080 for furnace lap and electric fusion welded pipe = 060 for furnace buttwelded pipe T = Temperature derating factor

Steel Materials

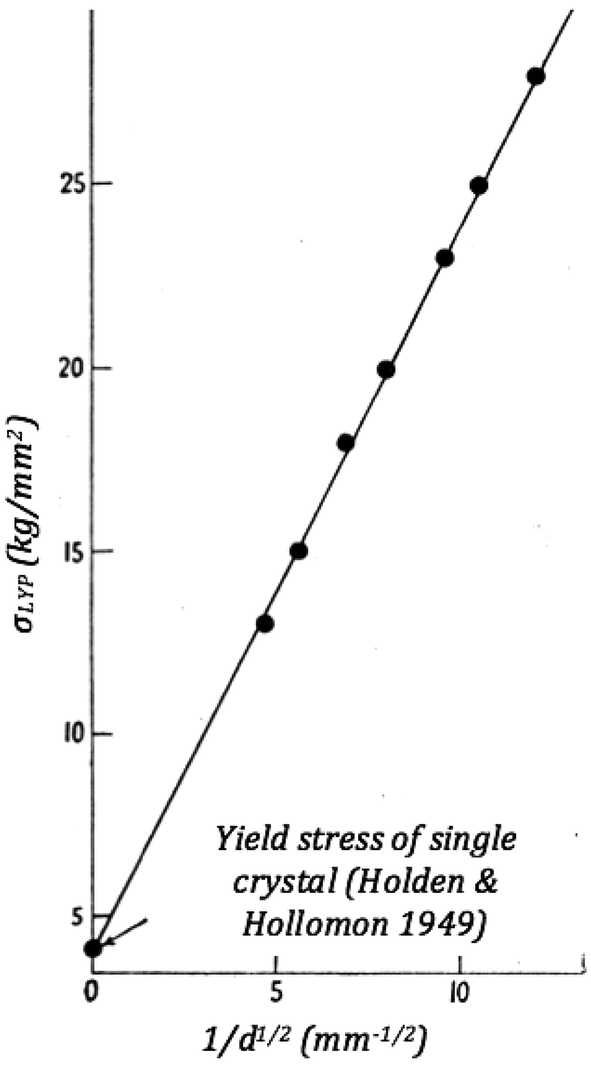

The Hall Petch And Inverse Hall Petch Relations And The Hardness Of Nanocrystalline Metals Springerlink

The strength of the electrode should match the strength of the base metal If yield stress (σy) of the base metal is ≤ 60 65 ksi, use E70XX electrode If yield stress (σy) of the base metal is ≥ 60 65 ksi, use E80XX electrode E70XX is the most popular electrode used for fillet welds made by the SMAW methodSpecifically, Barlow's Formula can be used to determine Internal Pressure at Minimum Yield S = SMYS minimum yield for grade of pipe;Twothirds of the specified minimum yield strength (which is at room temperature) Twothirds of the "minimum" yield strength at temperature Average stress for a minimum creep rate of 001%/1000 hours Twothirds of the average stress for creep rupture in 100,000 hours 80% of the minimum stress for a creep rupture in 100,000 hours

Ch 2 Stress Strains And Yield Criterion

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

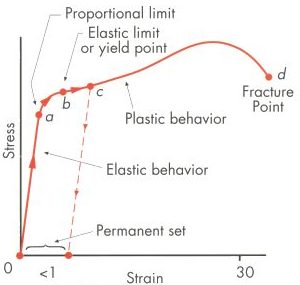

Ultimate Bursting Pressure S = SMTS minimum tensile strength for grade of pipe;Specified Minimum Yield Strength (SMYS) means the specified minimum yield strength for steel pipe manufactured in accordance with a listed specification This is a common term used in the oil and gas industry for steel pipe used under the jurisdiction of the United States Department of Transportation It is an indication of the minimum stress a pipe may experience that will cause plasticWhen yield strength is reported, the amount of offset used in the determination should be stated For example, "Yield Strength (at 02% offset) = 51,0 psi" Young's Modulus of Common Engineering Materials Some examples of yield strength for metals are as follows Typical StressStrain Curve Plastics

Steel Material Properties Steelconstruction Info

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

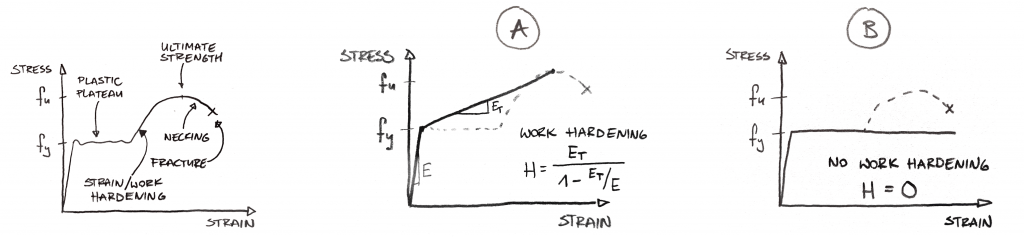

All three numbers are set as minimum (and occasionally maximum) values For example, according to ASTM A354, in order for a ½13 bolt to qualify as grade BD, it must have a minimum proof load of 17,050 poundsforce (lbf), a minimum yield strength of 18,500 lbf, and a minimum tensile strength of 21,300 lbfYield stress refers to the minimum stress at which a material will deform without significant increase in load In other words, the minimum stress required to make a material flow is the yield stress, and it is a measure of the strength of the material structure The stress at which yield occurs is dependent on both the rate of deformationYield stress and strength will now be sought Yield Stress Definition Consider a typical, ductile material stress strain curve as shown in Fig 1 Fig 1 Stress strain curve The related constitutive form will be taken to be that of the strain hardening type and applicable to any standard test such as those for

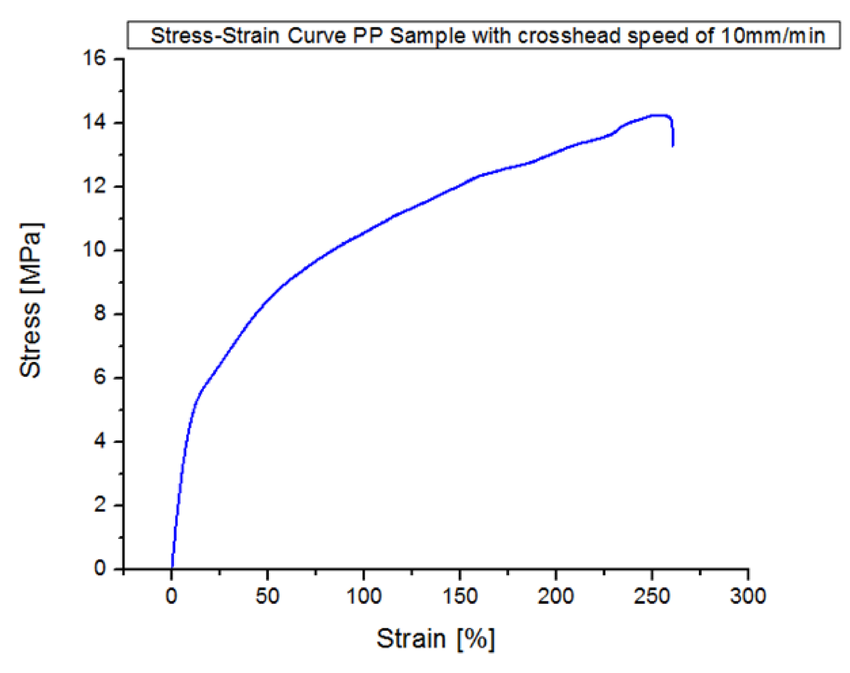

Tensile Test And Stress Strain Diagram Substech

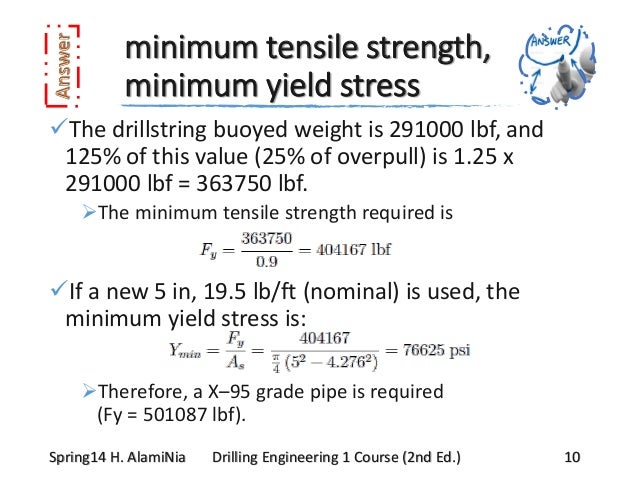

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

Maximum Bending Stress Equations σ π max = ⋅ ⋅ 32 3 M D b Solid Circular g σmax = ⋅ ⋅ 6 2 M b h σ a Rectangular f max = ⋅ = M c I M Z The section modulus, Z , can be found in many tables of properties of common cross sections (ie, Ibeams, channels, angle iron, etc) Bending Stress Equation Based on Known Radius of CurvatureUS Bolts Tensile Strength and Proof Loads ;The general formula for bending or normal stress on the section is given by Given a particular beam section, it is obvious to see that the bending stress will be maximized by the distance from the neutral axis (y) Thus, the maximum bending stress will occur either at the TOP or the BOTTOM of the beam section depending on which distance is larger

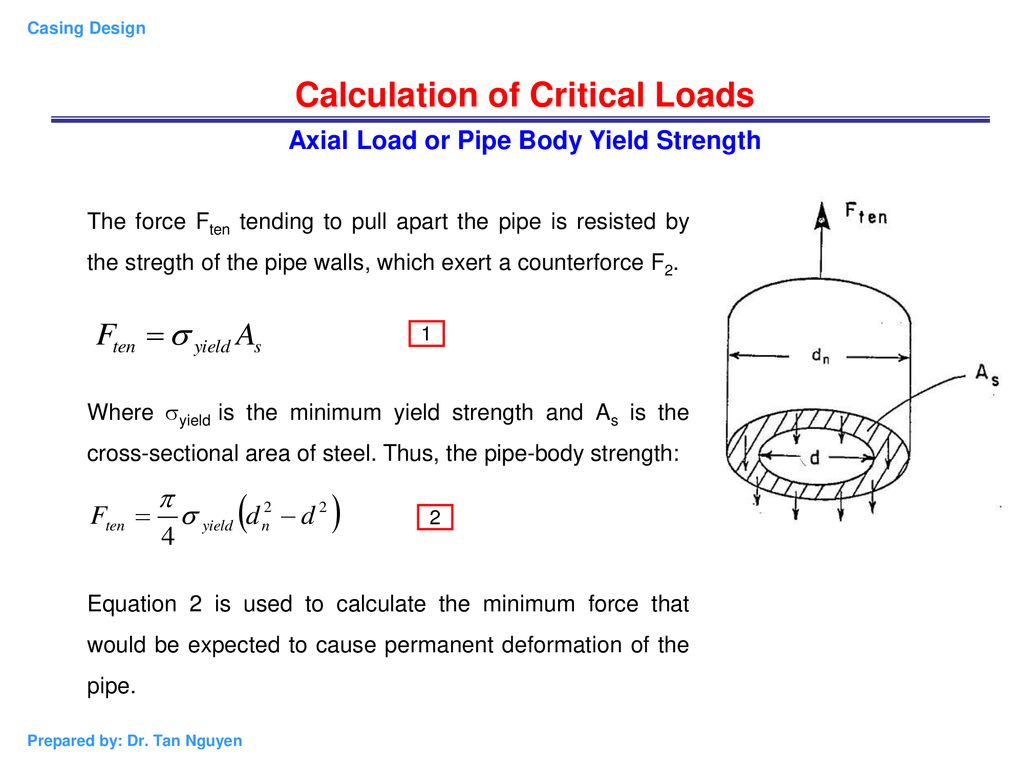

Chapter 2 Casing Design Calculations Of Loads On A Casing Ppt Download

Allowable Stress For Piping Materials As Per Asme 1 3

The stress at the point where the stressstrain curve deviates from proportionality is the yield strength of the material Some plastics' deformation is linearly elastic and once the maximum strength is attained, the material fracturesAllowable stress in psi, which depends on the pressure being determined utilizing Yield or Tensile depending on what is trying to be determined Specifically, Barlow's Formula can be used to determine Internal Pressure at Minimum Yield S = SMYS minimum yield for grade of pipe;Proof Load Proof load is defined as the maximum tensile force that can be applied to a bolt that will not result in plastic deformation A material must remain in its elastic region when loaded up to its proof load typically between 8595% of the yield strength

Ramberg Osgood Relationship Wikipedia

Strength At Break Tensile

The amount of stress at the safety load is called safety stress or yield stress and the amount of stress at the designated design load is called working stress So the design factor is the minimum requirement and safety factor is the limit beyond which the part will fail Here is a formula for reserve stress Reserve Stress= ProofWhere P = ID pressure (psi) T = Wall thickness (in) OD = Outside Diameter (in) *Must be a decimal* SF = Safety factor (generally 15 – 10, 1 for collapsing pressure) S = Material strength (psi) *Minimum yield strength*The strength of the electrode should match the strength of the base metal If yield stress (σy) of the base metal is ≤ 60 65 ksi, use E70XX electrode If yield stress (σy) of the base metal is ≥ 60 65 ksi, use E80XX electrode E70XX is the most popular electrode used for fillet welds made by the SMAW method

Critical Resolved Shear Stress Wikipedia

What S The Difference Between Bearing Shear And Tear Out Stress Machine Design

Yield stress refers to the minimum stress at which a material will deform without significant increase in load In other words, the minimum stress required to make a material flow is the yield stress, and it is a measure of the strength of the material structure The stress at which yield occurs is dependent on both the rate of deformation

Yield Strength Strength Mechanics Of Materials Engineers Edge

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

Strength At Break Tensile

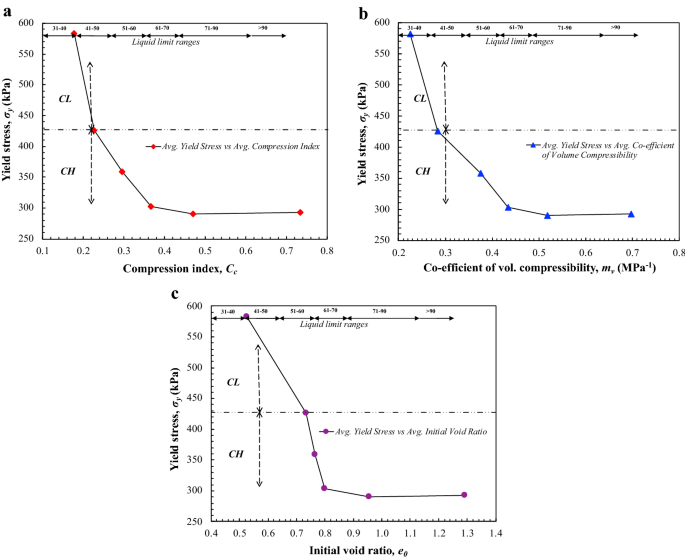

On Yield Stress Of Compacted Clays Springerlink

Stress In Finite Element Analysis Fea Part 3 Digital Engineering 24 7

What Is Proof Load Of A Bolt And How Is It Different From Yield Strength Smartbolts

.jpg)

Yield Stress Calculation Methods

1 1 11 Pipe Thickness Calculations Pipe Fluid Conveyance Strength Of Materials

How To Interpret Fea Results Enterfea

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Yield Strength Definition Examples Stress Strain Graph Faqs

Solved Question 1 The Eyebolt Is Made Of A Material Havin Chegg Com

What Is The Ultimate Tensile Strength And Yield Strength Of Mild Steel And Hysd Bar Quora

Allowable Stress In Asme Viii 1 3 Api 650 Api 653 Amarine

Material Properties

Steel Material Properties Steelconstruction Info

Yield Strength Of Steel Formula

Chapter 2 Casing Design Calculations Of Loads On A Casing Ppt Download

Thread Yield And Tensile Strength Equation And Calculator Engineers Edge Www Engineersedge Com

Careful Calculations Affect Ring Design

113 Questions With Answers In Yield Strength Science Topic

Help For Calculating The Max Allowable Pressure With The Pressure Piping Code Asme 1 3

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

How To Design For Stiffness Using Material Properties Fictiv

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Stress In Finite Element Analysis Fea Part 3 Digital Engineering 24 7

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

113 Questions With Answers In Yield Strength Science Topic

Material Properties

Tensile Testing Alex S Web Page

Gel Strength Sigma Quadrant Drilling Engineering Books

Minimum Yield Stress An Overview Sciencedirect Topics

Strength Of Materials Mechanics Of Materials Mechanicalc

Shear Yield Strength An Overview Sciencedirect Topics

.jpg)

Determining And Understanding The Yield Stress Of Complex Fluids

113 Questions With Answers In Yield Strength Science Topic

Engarc L Offset Yield Method

Yield Engineering Wikipedia

Cold Formed Steel Wikipedia

Q922 De1 L10 V1

Api 6a 21st Ed Gate Valves Design Allowables Valve Engineering Eng Tips

Yield Strength Of Steel Formula

Minimum Yield Strength An Overview Sciencedirect Topics

Minimum Yield Strength An Overview Sciencedirect Topics

Allowable Stress In Asme Viii 1 3 Api 650 Api 653 Amarine

Allowable Stress In Asme Viii 1 3 Api 650 Api 653 Amarine

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Yield Strength

Allowable Stresses Of Typical Asme Materials Carbon Steel

Specimen Thickness Effect

Yield Strength Strength Mechanics Of Materials Engineers Edge

How Can The Yield Strength Of Concrete Be Determined Quora

Solved A Ductile Hot Rolled Steel Bar Has A Minimum Yield Chegg Com

Yield And Tensile Strength Engineering Materials Youtube

Flow Curve And Yield Point Determination With Rotational Viscometry Anton Paar Wiki

コメント

コメントを投稿